Mode of operation:

This is similar to the BE-Fuelsaver, but it is only a small metal rod with a length of 30mm and a diameter of 8mm. To distinguish it has a hole in the middle. The BIO-ENERGETIC-Oil-Saver is fixed with a cable tie on a thin part (thin-walled) of the supply line to the oil burner, or even better directly in the oil filter (simply unscrew the sight glass at the bottom when the heating is switched off).

Application:

It is recommended to have the burner readjusted after 6-8 weeks (throttle the air supply) and possibly reduce the oil nozzle diameter by 0.1-0.5 mm so that it can be adapted to the new combustion conditions. Often the argument comes that the furnace soots up if you reduce the nozzle. However, this is not the case, as the modified combustion is more efficient and the carbon is burned better. The practice shows it !

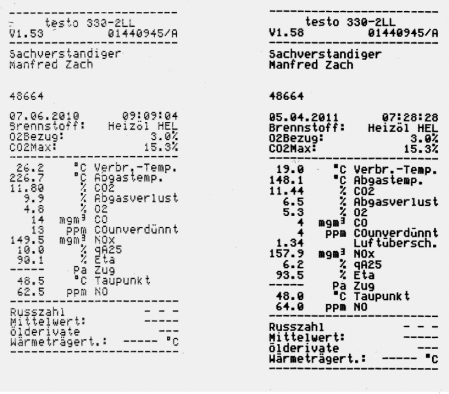

From the measurement on the right, you can see that the efficiency increases and the exhaust gas temperature decreases. Carbon monoxide (CO) is also decreasing. An excess of air is created, which should then be readjusted after approx. 6-8 weeks, as described above, in order to further optimize the system. It was also possible to use the pen to make old oil heating systems fit again, which no longer achieved the required efficiency of 90% (= exhaust gas loss of less than 10%) and emitted too much CO. A simple way to "renovate" old equipment.

Measurement

Exhaust gas temperature has dropped 78 degrees and CO levels have been reduced.